Crush Cut Rotary Dies

WHY CHOOSE BERNAL CRUSH CUT DIES?

Die Cutting Tooling, Segmented Rotary Dies, Scrap Stripping Dies, Machine Sharpening

Bernal invented the solid hardened rotary die in the late 1960's by generating a wedge-type cutting edge on a solid hardened cylinder using EDM (electrical discharge machining)…now a proprietary process. Since then, thousands of rotary dies have achieved high-quality cuts, at the highest speeds, in countless materials and products.

Bernal invented the solid hardened rotary die in the late 1960's by generating a wedge-type cutting edge on a solid hardened cylinder using EDM (electrical discharge machining)…now a proprietary process. Since then, thousands of rotary dies have achieved high-quality cuts, at the highest speeds, in countless materials and products.

Examples include: folding cartons, disposables, medical bandages, printed circuits, batteries…even snack foods.

WHAT ARE THE BENEFITS?

Bernal Crush Cut Rotary Dies are solid, tool steel, high-hardness rotary dies, made to cut continuous webs of material. They are manufactured to exacting tolerances to assure you of the most precise die cuts possible. Smooth rotational cutting provides cleanliness of cut and the highest possible speeds and through-put.

Features and benefits include:

- Machine Sharpening

- Solid Steel Dies

- Partially or Fully Segmented Dies

- Quick-Change

- Fully-Hardened

- Precise Cutting Shape Tolerances

- High-Speed Operation

- Scrap Stripping

RESHARPENING

Dies can be resharpened numerous times, so a die achieving 10 million revolutions before each resharpening will ultimately achieve millions of revolutions during its total die life. Each time the die is resharpened, cut quality is renewed to that of a new die.

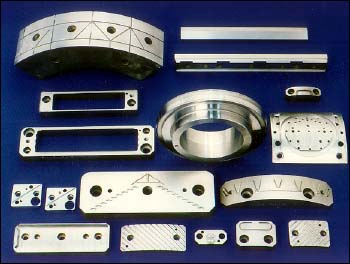

PARTIALLY OR FULLY SEGMENTED ROTARY DIES

Crush Cut Dies are available with specially designed segments and removable rings for a wide variety of applications - not only cutting, but embossing, marking and laminating. Removable segments can make a generic carton die useable for several end-customers by simply changing customer-specific segments. This spreads the cost justification of one die set over multiple customers.

SPECIFICATIONS

SPECIFICATIONS

High-precision aerospace machining techniques are the first steps in long die life. Our Advanced Machining Lab ensures that your die is manufactured to the highest standards, using CAD/CAM, CNC and CMM methods, as well as EDM.

- Cutting edge accuracy...............to .001"(.025mm)

- Web widths................................from 1" to 110" (50mm to 2794mm)

- Die diameters ...........................from 3" to 40" (76.2mm to 762.0mm)

- Run-out accuracy......................to .0001"(.0025mm)

- hardness...................................60-62 Rc

- Resharpenings..........................up to 5

CRUSH CUT DIE LIFE COMPARISONS

CRUSH CUT DIE LIFE COMPARISONS

- SBS Board 40 Mil. Revs

- Poly Board 80 Mil. Revs

- Lead 8 Mil. Revs

- PVC 5 Mil. Revs

- Sandpaper 2 Mil. Revs

Typical Materials

Typical Materials

- Poly Board

- Cloth

- Lead

- Sandpaper

- Polypropylene

- Paper

- Recycled Board

- Dough

- Non-woven

- Laminates

- Fiberglass

- Copper