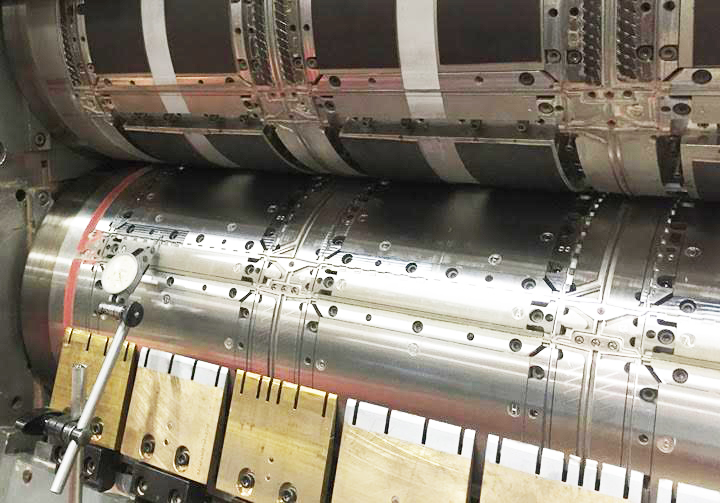

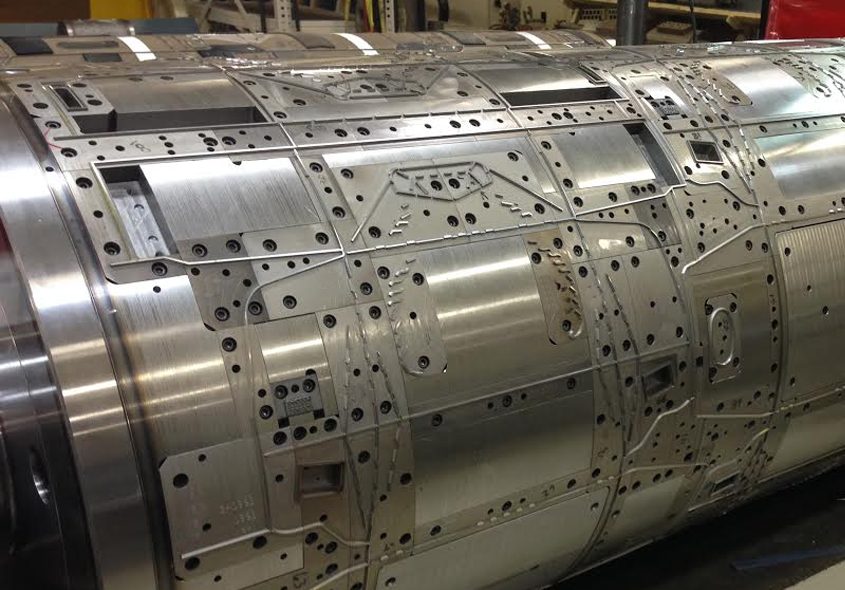

Rotary Dies - RP® Dies ( Rotary Pressure)

WHY CHOOSE BERNAL RP DIES?

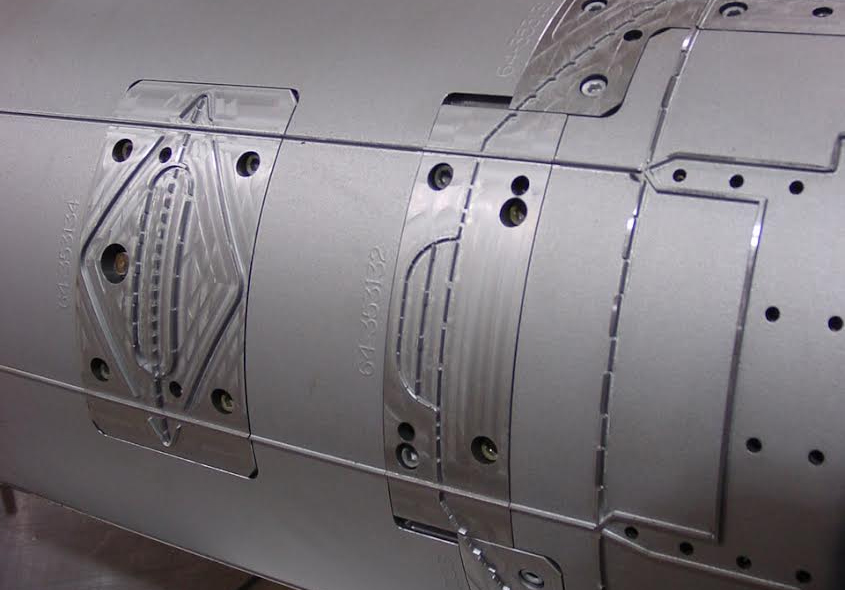

Bernal RP dies represent breakthrough technology in the folding carton industry. They provide significantly longer die life than conventional rotary dies, while maintaining like-new cutting quality. How can we do all of this? Through the use of "shearing" blades, instead of crushing blades, on both the upper die and the lower die.

Bernal RP dies represent breakthrough technology in the folding carton industry. They provide significantly longer die life than conventional rotary dies, while maintaining like-new cutting quality. How can we do all of this? Through the use of "shearing" blades, instead of crushing blades, on both the upper die and the lower die.

The RP "shearing" action results in the very highest level of cut quality. Bernal offers a variety of RP die choices, including various steel alloys, several hardening techniques, and designs with and without journals. Whatever your needs, we have a die priced to generate the lowest cost-per-thousand for most carton volumes.

WHAT ARE THE BENEFITS?

RP dies, with their exceptionally strong blade design and long life, allow an operator to forget the die cutting part of the process and focus on other areas. Untimely damage to cutting blades can be repaired by Bernal repair department or by your own personnel, often in your own plant.

RP DIES DELIVER

- Cleanliness of cut

- Durability

- Burr-free cutting

- Low operator maintenance

- High speed

- In-die scrap stripping

- Creasing/scoring & embossing

CROSSOVER TECHNOLOGY

Crossover Technology allows us to place all of the upper cutting edges on one side of the cut, across and around the die. This allows us to move the upper and lower cutting edges closer together…by making a side position adjustment for blades running around the die, and by making a rotational position adjustment for blades running across the die. This feature gives the operator die life adjustment and cut quality adjustment.

Crossover Technology allows us to place all of the upper cutting edges on one side of the cut, across and around the die. This allows us to move the upper and lower cutting edges closer together…by making a side position adjustment for blades running around the die, and by making a rotational position adjustment for blades running across the die. This feature gives the operator die life adjustment and cut quality adjustment.

CLEANLINESS OF CUT

The elimination of the standard crush-type cut and the use of a "shear"-type cut with no metal-to-metal die contact results in a cleanliness of cut that all but eliminates chaff, slivers and ragged cuts. Simple side and rotational adjustments allow this cut quality to be maintained for a high percentage of the die life cycle, instead of the steady degradation of crush cut.

MATERIALS / PRODUCTS

RP Rotary Dies cut without metal-to-metal contact, which extends die life. To do this, RP cutting relies on bursting the final part of the cut. Ideal materials for RP cutting are high-density materials, including abrasive materials. RP dies can be changed over in their modules in a matter of minutes. But the real success of RP dies is measured in durability, uptime and productivity. These factors consistently produce the lowest-possible cost-per-thousand and increased line capacity.

RP Rotary Dies cut without metal-to-metal contact, which extends die life. To do this, RP cutting relies on bursting the final part of the cut. Ideal materials for RP cutting are high-density materials, including abrasive materials. RP dies can be changed over in their modules in a matter of minutes. But the real success of RP dies is measured in durability, uptime and productivity. These factors consistently produce the lowest-possible cost-per-thousand and increased line capacity.

Products:

- Gable Top Packaging

- Aseptic Packaging & Pouches

- Beverage Carriers

- Frozen Food Cartons

- Paper Cups

- Cereal Cartons

- Overnight Mailer Envelopes

- Cigarette Cartons

- Liquor Cartons

- Fast Food Cartons

- General Folding Cartons

- and many more...

RP Rotary Die Specifications:

RP Rotary Die Specifications:

- 10 to 500 million revolutions before sharpening

- Solid, Partially or Fully Segmented Construction

- Cuts material thickness up to .125" (3.175mm)

- Die diameter range: 3" to 30" (76.2mm to 762.0mm)

- Lowest cost-per-thousand in most volumes

- Web width of 1” to 110” (25mm to 2794)

- Multiple resharpenings

- Materials - paperboard, high-density plastics, masonite, corrugated, recycled board, coated boards.