Rotary Converting Systems

Purpose Built Converting Systems, Special Machine Systems, Custom Web Fed Systems

WHY CHOOSE BERNAL ROTARY SYSTEMS?

Bernal designs and manufactures custom converting equipment to your specifications. We have over 45 years of experience designing high speed, high efficiency, continuous web converting systems for a variety of end products at web widths from 1 inch to 110 inches. This includes integrating our equipment with existing, new or developmental equipment. Our customer list includes Fortune 500 companies in packaging, medical, automotive, consumer products, food products, batteries, disposables and aerospace to name but a few.

Bernal designs and manufactures custom converting equipment to your specifications. We have over 45 years of experience designing high speed, high efficiency, continuous web converting systems for a variety of end products at web widths from 1 inch to 110 inches. This includes integrating our equipment with existing, new or developmental equipment. Our customer list includes Fortune 500 companies in packaging, medical, automotive, consumer products, food products, batteries, disposables and aerospace to name but a few.

Bernal systems have used a variety of techniques including die-cutting, punching, ultrasonic sealing, heat sealing, laminating, vacuum transfer, folding, counting, pouching, embossing, heating, chilling, and stacking. Bernal world class service department supports and maintains production operation commitments around the globe.

STANDARD COMPONENTS

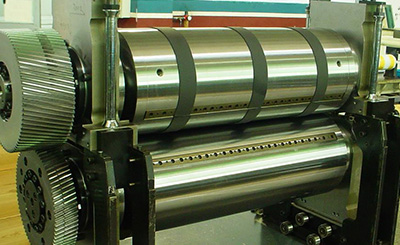

Bernal has families of standard components that become the basis for custom system designs. These families include bearing housings, die cutting modules, infeeds, unwinds, rewinds, vacuum transfer stations, heat seal stations, delivery systems and stackers. Bernal system designs cover web widths from 1 to 110 inches, speeds from 10 to 1500 fpm.

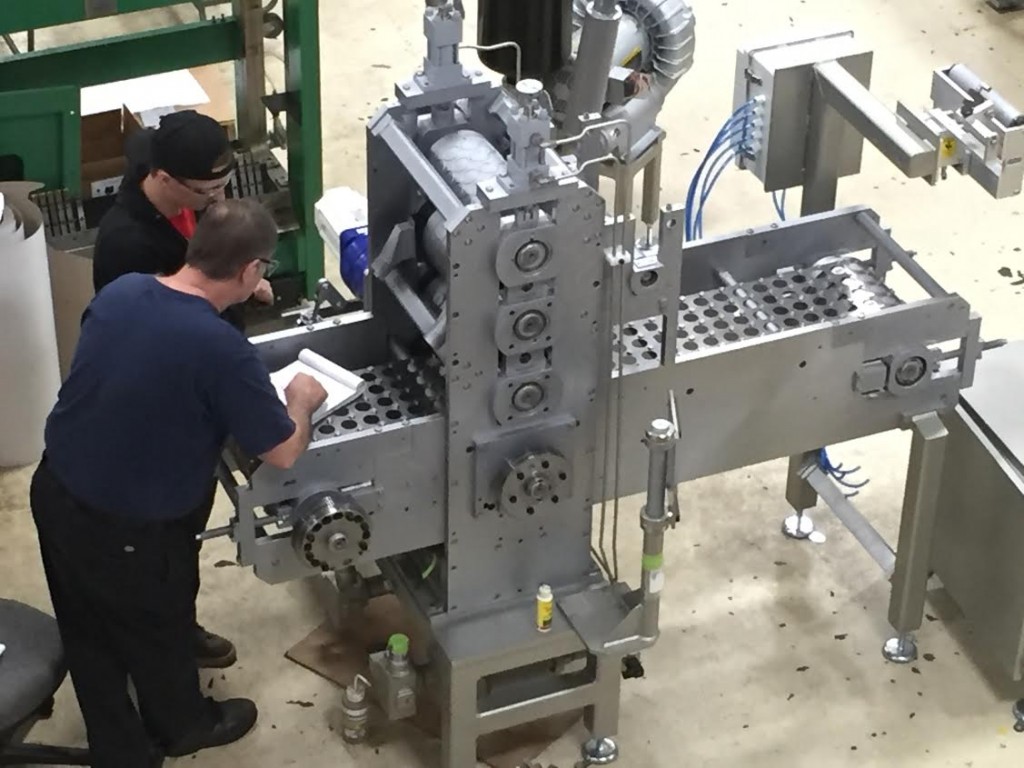

Modular Design

Bernal systems are based on standard and custom designed modular stations. Custom stations are comprised of standard as well as custom designed subassemblies. In many cases these modular stations allow for quick product changeovers.

Bernal systems are based on standard and custom designed modular stations. Custom stations are comprised of standard as well as custom designed subassemblies. In many cases these modular stations allow for quick product changeovers.

Custom Engineered to Meet Your Needs

If your product is adaptable to web processing, and includes multiple cutting and assembly operations you can look forward to higher productivity and lower unit costs with a manufacturing system from Bernal. We can also provide you with modular sections for you to adapt to your system. Bernal has provided proof of principle, prototype, pre-production and production systems as required. We can provide you with the system you need.

Operational Bernal Systems

Operational Bernal Systems

- Batteries

- Can Lids

- EKG pads

- Abrasives

- Cartons

- Filters

- Bandages

- Snack Foods

- Cooling fins

- File Folders

- Bags

- Pouches

- Cups

- Cereal

- Alcohol Swabs (Prep Pads)

- and many more...

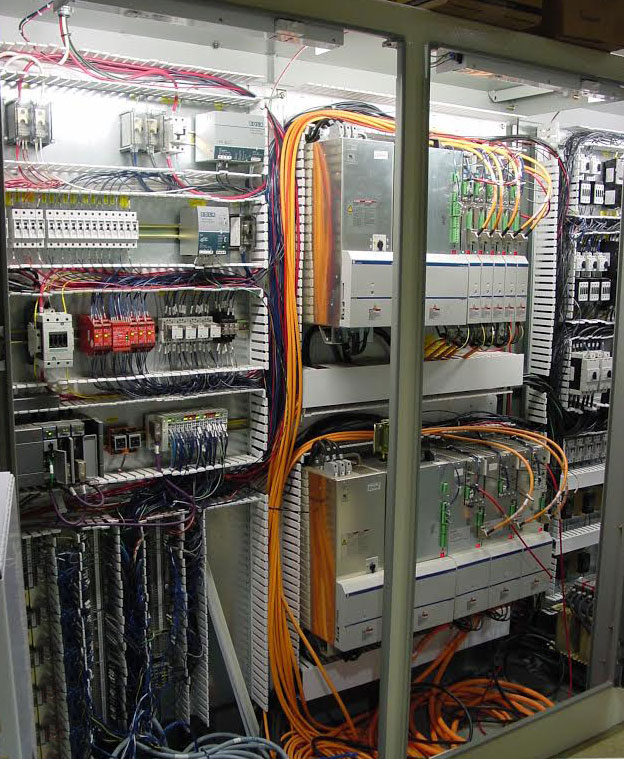

ELECTRONIC DRIVES & SYSTEM CONTROL

Bernal provides the latest microprocessor controlled drives, PLC's, production data acquisition and system controls. We have print and part registration software and have integrated visual inspection and other real-time Q.C. systems. With our experience we are able to interface with other equipment such that the control system becomes transparent. Our system controls have produced system efficiencies as high as 99%.

Bernal provides the latest microprocessor controlled drives, PLC's, production data acquisition and system controls. We have print and part registration software and have integrated visual inspection and other real-time Q.C. systems. With our experience we are able to interface with other equipment such that the control system becomes transparent. Our system controls have produced system efficiencies as high as 99%.

FEATURES

Bernal systems feature the latest technology backed up with aerospace quality machining centers and Q.C. equipment, C.A.D. / C.A.M., a staff metallurgist and a world class engineering group.

Single-source responsibility

Single-source responsibility- Inspection systems

- Food grade systems

- High accuracy cutting and assembly

- Print and part registration

- Precise tension control

- Rapid changeovers

- Systems integrator

- Compatible with all die types

- Roll-to-roll or roll-to-finished part

- Temperature-controlled oil lubrication

Complete System Responsibility

When Bernal designs a converting system we take full responsibility for the entire system. System designs are reviewed with you prior to build. Systems are assembled at Bernal and approved by you for speed and performance prior to shipping. Our personnel direct the installation, commissioning, final approval, training and start-up at your facility.

Die Options

Bernal's core product, rotary dies, are proven in countless applications. Rotary dies are available to cut, sheet, form, emboss, vacuum transfer, heat seal, and ultrasonic seal. Many dies feature removable segments to allow cutting and embossing in one die or to vary features with applications. These dies are mounted in precision bearing housings that allow them to be easily removed from the station for product changes. Dies can be changed in as little as one minute. Die life varies with the materials ranging from 1 to 500 million revolutions.