Die Cutting Modules & Cassettes

WHY CHOOSE BERNAL DIE CUTTING MODULES & CASSETTES?

Bernal modules are designed to maximize die performance. Our 45-plus years as a premier die manufacturer goes into every module design, so you are assured of precision die cutting and trouble-free operation. Thanks to an advanced-capability machine shop, Bernal modules achieve the highest precision in the industry. They come in many standard and custom designs, to suit a wide variety of applications, including folding cartons, medical supplies, consumer products, batteries, foods, and many others. After installation, Bernal can keep your module in like-new condition with periodic inspection and service during die resharpening. We can replace any worn parts from our extensive spare parts inventory. In addition, Bernal welcomes the opportunity to provide the highest quality modules/cassettes and rotary tooling for owners of competitors equipment. Contact Bernal today to see what we can do for you.

Bernal modules are designed to maximize die performance. Our 45-plus years as a premier die manufacturer goes into every module design, so you are assured of precision die cutting and trouble-free operation. Thanks to an advanced-capability machine shop, Bernal modules achieve the highest precision in the industry. They come in many standard and custom designs, to suit a wide variety of applications, including folding cartons, medical supplies, consumer products, batteries, foods, and many others. After installation, Bernal can keep your module in like-new condition with periodic inspection and service during die resharpening. We can replace any worn parts from our extensive spare parts inventory. In addition, Bernal welcomes the opportunity to provide the highest quality modules/cassettes and rotary tooling for owners of competitors equipment. Contact Bernal today to see what we can do for you.

FEATURES & BENEFITS

FEATURES & BENEFITS

Side, bottom and top plates are stress-relieved, precision-machined and assembled in highly rigid box sections. All Bernal modules include bearing housings of our own design and manufacture, with print class, precision-matched bearings.

Key features and benefits include:

- In-module pin stripping

- Rapid changeovers

- Maximized die life

- Compatible with all types of rotary dies

- In-stock spare parts

- Single-source die and module responsibility

- Highly rigid box construction

- Precision bearing housings

- Rigid stripping comb assemblies

- Temperature-controlled oil lubrication

- Grease lubrication

- Side, rotational and skew bearing adjustments

- Available in journaled and journal-less versions

MODULES FOR EVERY DIE CUTTING OPERATION

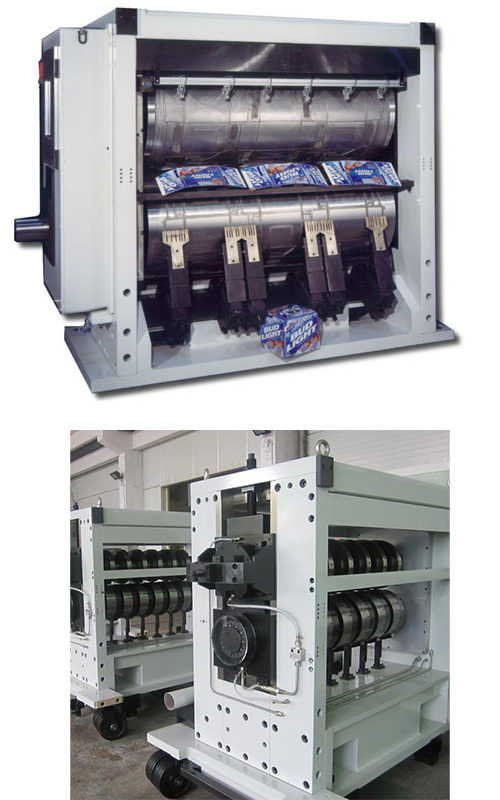

The precision module is the mechanical environment that allows a die to operate at its highest speed… and achieve its longest life. Bernal modules' rigid construction eliminates the flex that causes premature die wear and poor cut quality. They are used with RP, crush cut, male/female, and embossing dies.

Single-Slot Modules

Single slot modules carry four bearing housings in which the upper and lower tools are mounted. This type of module is offered with and without in-module stripping capability.

Single slot modules carry four bearing housings in which the upper and lower tools are mounted. This type of module is offered with and without in-module stripping capability.

Dual-Slot Modules

Dual slot modules are recommended when extreme precision between first and second station tooling is required, as this arrangement allows two tool sets to be removed and kept in register with each other. Most dual slots are of a base-mounted, roll-in style, so the module can roll onto a set-up platform that is moved about the plant by lift truck. Our newest design is a floor-mounted, roll-in style that is moved out of its place in the system, and around the plant, on its own rollers, pulled by an electric tug.

Dual slot modules are recommended when extreme precision between first and second station tooling is required, as this arrangement allows two tool sets to be removed and kept in register with each other. Most dual slots are of a base-mounted, roll-in style, so the module can roll onto a set-up platform that is moved about the plant by lift truck. Our newest design is a floor-mounted, roll-in style that is moved out of its place in the system, and around the plant, on its own rollers, pulled by an electric tug.

Custom Designed Modules

Where standard designs are not appropriate, Bernal designs custom modules. For many customers, we have designed modules to fit into other manufacturers' rotary cutting systems. Examples of special applications include food grade stainless steel modules and specially-sized modules to fit existing space and machinery constraints.

Where standard designs are not appropriate, Bernal designs custom modules. For many customers, we have designed modules to fit into other manufacturers' rotary cutting systems. Examples of special applications include food grade stainless steel modules and specially-sized modules to fit existing space and machinery constraints.

Scrap Removal Solutions

Bernal offers a variety of stripping methods to remove continuous scrap and island scrap. In-tool stripping has a pin mounted in the lower tool to skewer the scrap, and a stripping comb mounted to a rigid assembly to lift the scrap off the pin so it can be vacuumed away. We can also provide outboard stripping, in which the stripping pins — which may be fixed or retractable — are in a separate cylinder, in a separate station. Male/female stripping is another alternative.

Module Bearings

Bernal has a family of bearing housing designs for modules from 2" to 110" (50mm to 2794mm) in width. Each is custom-designed and manufactured to precise specifications and is available with oil or grease lubrication. Bernal bearings use print class-matched tapered roller bearings that mount to tapered die journals and are designed for speeds up to 1,500 fpm (457 mpm).